Welcome to Dongzhan Drive Industry (Shanghai)Co.,Ltd.

Dongzhan Drive Industry (Shanghai)Co.,Ltd. was established in 2011. From the beginning of its establishment, it has been upholding to provide customers with high-quality, reliable and efficient power, transmission and control solutions.

The company established its own production base in 2014 and currently has more than 80 employees, of whom about 45% are non-frontline operators. These personnel are active in the R & D department, sales service department, incoming inspection production line, process inspection production line, etc. which afford a strong guarantee of reliable quality and continuous improvement.

Products

Transmission Series

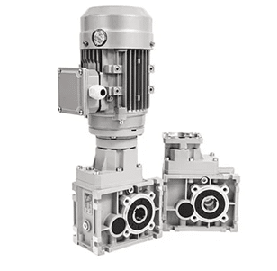

Gearhead with IEC Flange

IEC Metric Frame Motors are specifically designed for the needs of our customers utilizing equipment manufactured overseas. WorldWide Electric’s IEC motors operate at IE3 Efficiency at 50 Hz and are NEMA Premium Efficient at 60 Hz operation. Features include an aluminum frame, a multi-mounting frame design, a vacuum pressure impregnation system, and CE and IEC60034-1 certifications.

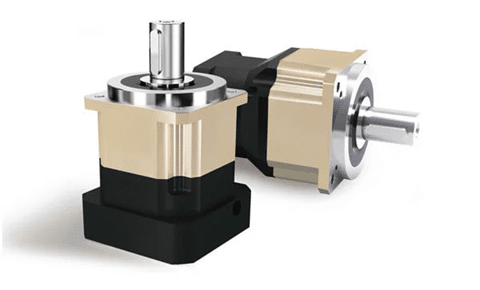

Precision Planetary Gearbox

Precision Planetary Gearbox is a transmission structure. It mainly consists of three parts: planet gear, sun gear and inner ring gear. It has a simple structure and high transmission efficiency. It is installed on a servo motor to reduce speed, increase torque and achieve accurate positioning. Widely used in CNC machine tools, industrial robots, service robots, robots, food machinery, packaging machinery; laser cutting machines, woodworking engraving machines, printing machinery and other automation equipment.

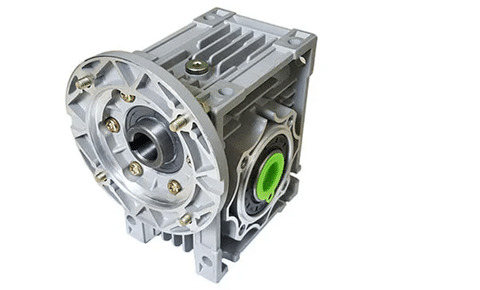

Worm Gearbox

The worm gear is an essential mechanical transmission method consisting of three parts: worm gear, worm gear, and gear. A worm is a long rod with spiral teeth, while a worm gear is a disc with a spiral flange. When the worm rotates, the spiral flange of the worm gear will guide the worm to reciprocate on its axis, thus achieving a high reduction ratio transmission effect.

Specifically, the function of the worm gear is to convert the high-speed rotating input shaft into a low-speed rotating output shaft. At the same time, different transmission ratios and speed adjustments can be achieved by changing the worm’s helix degree and the worm gear’s number of teeth. In addition, the worm gear can also achieve self-locking and anti-reverse effects, which is very important for some mechanical devices that need to prevent reversal and maintain position.

Hypoid Gearbox

Hypoid gears are widely used in machine tools and can be used in the transmission systems of CNC machine tools, grinders, milling machines, punches, and other equipment. Hypoid gears have the characteristics of smooth transmission and high precision, which can ensure the stability and accuracy of machine tools and improve the processing quality and efficiency of machine tools.

Hypoid gears are widely used in aircraft engine transmission systems. Compared with traditional equipment, hybrid bags can reduce vibration, noise, and wear in transmission, improving engine reliability and service life. At the same time, the hypoid gear has high precision and can meet the requirements of high-speed rotation.

In short, hypoid gears have the characteristics of smooth transmission, low noise, and high precision and have been widely used in machine tools, aircraft, ships, and other fields. With the continuous development of science and technology, the application fields of hypoid gears will continue to expand.

Power Series

DC Motors

A DC motor is a rotating device that converts DC electrical energy into mechanical energy. The stator of the motor provides the magnetic field, the DC power supply provides current to the windings of the rotor, and the commutator keeps the direction of the rotor current and the torque generated by the magnetic field unchanged. DC motors can be divided into two categories according to whether they are equipped with a commonly used brush-commutator, including brushed DC motors and brushless DC motors. DC motors are suitable for many different application scenarios, such as industrial production, household appliances, transportation, aerospace, robotics and other fields.

AC Motors

A motor is a device that converts electrical energy into mechanical energy. According to different power signals, motors can be divided into two types: AC motors and DC motors. AC motor refers to a motor that uses AC power as its power source. Its main feature is that the speed is unstable but its torque is large. DC motor refers to a motor that uses DC power as its power source. Its main feature is that its speed is stable but its torque is relatively large. smaller. AC motors and DC motors have their own application scenarios in different fields. AC motors are widely used in high-power load applications such as elevators, air conditioners, compressors, and water pumps; DC motors are widely used in electric vehicles, wind turbines, robots, and other applications that require high-speed and precise control.

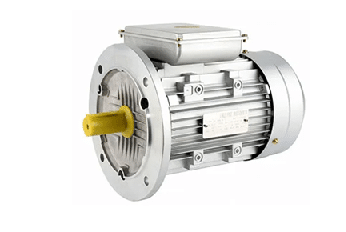

AC Asynchronous Motor

An AC asynchronous motor is a motor that operates through rotating magnetic fields at different speeds. It was created by Brazilian engineer Nikola Tesla and several others and is more common and practical than the synchronous motor. AC asynchronous motors are used in various applications, including manufacturing, transportation, and home appliances.

AC asynchronous motors, such as industrial machinery, machine tools, water pumps, compressors, fans, and other equipment, are widely used in manufacturing industries. They are also commonly used in household appliances such as vacuum cleaners, refrigerators, washing machines, etc. In addition, AC asynchronous motors are also used in transportation equipment such as elevators, subways, and high-speed rails.

Helical Gear Motor

Helical gears are frequently used in automotive engines, steering systems, and transmissions. Helical gears drive the entire mechanical system to provide power to automobile engines. In steering systems, helical gears can reduce the motor’s load and increase the steering system’s efficiency. In a transmission, helical gears can better match other packs and improve the transmission’s performance. Because of the taper of the tooth surfaces of helical gears, they drive Helical gears can withstand high loads better than other gears when transmitting higher power or torque. This helps improve machine reliability and longevity.

Helical gears are widely used in industrial machinery manufacturing to transmit power and reduce noise. They are used in various applications, including automobiles, aircraft, and heavy machinery. Helical gears have higher transmission efficiency, lower noise levels, and better load distribution than other kits.

Contral Series

Controller for Brushed DC motor

A DC motor controller is a special type of gear motor electrical device that converts electrical energy into mechanical energy. A DC motor receives electrical energy by utilizing direct current and then converts this energy into automatic rotation of the motor. DC motors are used almost everywhere. They utilize the magnetic field created by the current that drives a rotor fixed on the output shaft. The speed and output torque depend on the design of the motor and the electrical input.

Application areas of DC motor controllers:

There are various DC motors on the market now and we use them extensively. At home, DC motors can be used in toys, tools and other household appliances. In the industrial sector, their needs include running across carousels to conveyors, as well as reverse. DC motors are used to power pumps based on their excellent motion responsiveness and ease of speed change, and they are preferred for fans due to their energy-saving mechanism. DC motor toys come in a variety of voltages and therefore require different types of motion and speed. DC motors are preferred for electric vehicles because of their durability and energy efficiency. Electric bikes have DC motors in both the rear and front wheel hubs to achieve the required power levels and torque.

Drive for Brushless DC Motor

Motors and a wide range of motion control applications have been rapidly adopted in the market because of their distinct advantages over traditional brushed DC motors. Less maintenance, higher operating speeds, compactness, less electrical noise, and better torque-to-weight ratio, to name a few. Despite these advantages, BLDC motors cost more than conventional DC motors because they require a motor drive controller (for electronic commutation) and a rotor position sensor.

When the motor of the brushless motor driver rotates, first, the control unit must determine the order of turning on (or turning off) the power transistors in the inverter according to the position of the motor rotor sensed by the hall-sensor, and then based on the stator winding.

Controller for Single-phase AC motor

Single-phase motor speed controller is a power control device used to control the speed of single-phase motors. A single-phase motor refers to an AC motor with only one phase and is commonly used in household appliances and small mechanical equipment. The single-phase motor speed controller can change the speed of the motor by adjusting the voltage and frequency of the motor, thereby achieving speed control of the motor. Single-phase motor speed controller usually includes voltage regulator, frequency converter and control circuit. At present, research on single-phase motor speed controllers mainly focuses on improving speed regulation accuracy, reducing costs, and enhancing control functions. Researchers are developing new control algorithms and circuit designs to improve the control accuracy and stability of single-phase motor speed controllers. With the development of intelligent and automation technology, single-phase motor speed controllers will become more intelligent and automated. More efficient control algorithms and intelligent control systems will emerge to achieve more stable speed control. In addition, with the development of motor technology, single-phase motor speed controllers will become more intelligent and efficient to meet people’s growing needs for motor speed control.

Inverter for Three-phase AC motor

A three-phase inverter is a power conversion device that converts direct current into alternating current. It can convert electric energy from DC power sources such as solar energy and wind energy into AC electricity required for household or industrial electricity, and is widely used in the field of renewable energy power generation. Three-phase inverters can be divided into two categories according to their topology: bridge type and non-bridge type. Among them, the output voltage waveform of the three-phase inverter with a bridge is relatively close to a sine wave, and is suitable for applications that require high-quality power, such as medical equipment; while the three-phase inverter without a bridge is generally cheaper and suitable for applications Price-sensitive markets such as commercial street lighting. Three-phase inverters can be used in various fields, especially renewable energy power generation and industrial automation control. Renewable energy power generation: Renewable energy sources such as solar power and wind power need to convert DC power into AC power through an inverter before they can be put into the grid. Industrial automation control: Three-phase inverters can be used in high-performance servo drive systems, including CNC machine tools, textile machinery, printing machinery, plastic machinery and other fields. Household applications: such as air conditioners, lighting, and kitchen appliances,

https://www.dzgearmotor.com/

Address

No. 186, Dongri Road, Zhujing Town, Jinshan District, Shanghai, China.

Email:sales@dzgearmotor.com

Phone: +86-18019434030

Working Hours: Monday-Friday, 8am to 6pm