With rapid development, PENTA LASER is introduced to Wenzhou city as an important industrial project with the overall investments of 500 million RMB, and the annual production capability is up to 4 billion RMB. We built service and training centers in 35 major Chinese cities and more than 10 countries all over the world.

PENTA LASER sticks to its principle of quality first, innovation driven and services oriented, as the laser cutting and welding expert, we expect to create the laser application revolution in the smart manufacturing era and create value for clients.

3 Manufacture Plants: WenZhou,WuHan, ShanDong

Global Market and Service Center: 36 Domestic Service Centers,9 Overseas Service Centers

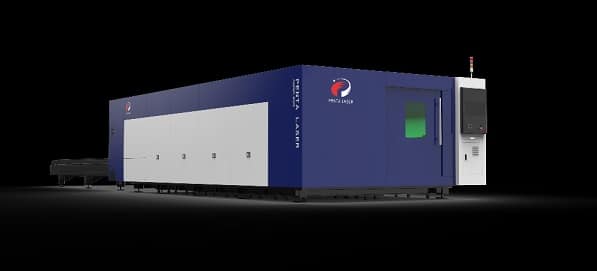

Suitable for rapid cutting of medium and thin plates. Widely used in sheet metal processing, lighting, kitchenware, decorative materials, chassis cabinets and other industries.

Able to cut medium and thin carbon steel, stainless steel,galvanized plate, aluminum alloy, brass, etc.

Equipped with specialized high-power laser cutting head, to ensure the machine a long-time running with efficiency and stability. Auto-focus and rapid perforation, unique 360° anti-collision, shining cutting, sharp Angle cutting and precision cutting technology, make it a precision parts manufacturing tools

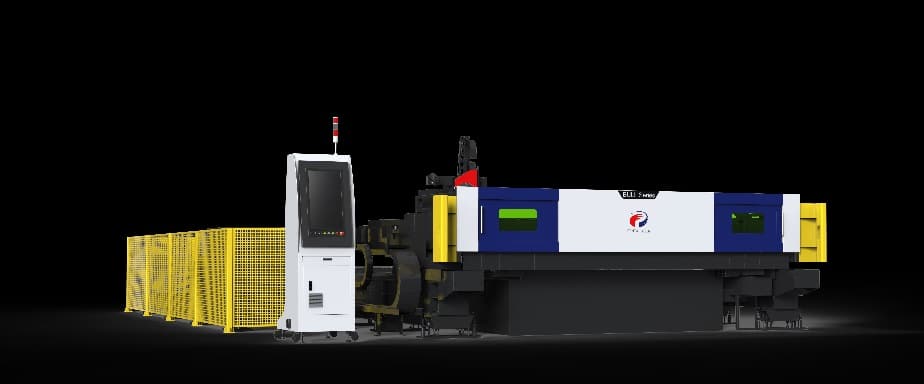

Cost-effective, entry level, two model type pipe cutting machine optional. Two chuck pipe cutting special for tiny pipe cutting and three chuck pipe cutting special for heavy pipe cutting. Two or three chuck plus floating support. Automatic floating support system, complete cutting, automatic blanking, cutting efficiency is better than three chuck structure

Multiple processes are completed at once, the processing speed is fast, the precision is high, and the applicable types of pipe materials are many Save labor, save process, save plant, save fixtures, improve accuracy, increase efficiency

Auto Loading System Optional

Whirl-Plus mainly applies for processing round tube, square tube, oval tube and other shaped products. Comparing with conventional cutting methods, it works flexibly to decrease new products developing cycle since no mold is required. Automatic loading system available, for decreasing labor cost, increasing cutting efficiency

Portable Mainframe: Laser aource and chiller are integrated in one machine, easy to move; Upper and lower layer design for heat source isolation,Ensuring working enviornment of laser source; easy to dismant and maintain

Professional welding system for synchronous rotating parts. By optimizing the arrangement of optical axis and the incidence Angle of laser beam, this system can complete the welding of cylindrical parts with the size of 5-400mm.

3D Fiber Laser Cutting Machine

Adopt imported Italy ELEN special 3D cutting head and Z32 Smart Manager 3D CNC control system. PENTA LASER 3D laser cutting machine rely on 25 years of engineering research. From the rotating systems to the stable accessible structure, everything is specifically designed to achieve the best performance in the five-axis cutting. Flexibility and precision are the keywords underlying the design of PENTA LASER five-axis cutting systems.

The pictures above are for reference only, for more information please visit the following websites:

https://pentalaser.com/en/