Welcome to Rapid Engineering

Rapid Engineering is a company dedicated to providing high-quality laser cutting and welding machines. Our focus is on delivering machines known for their efficiency, precision, and cutting-edge technology.

Here’s what we do:

Laser Cutting

Our laser cutting machines offer exceptional precision and efficiency, are versatile for various materials and thicknesses, and utilize advanced technology to enable the crafting of intricate designs and parts with ease.

Innovation and Creativity

Discover the power of precision and efficiency with our cutting-edge technology. Our machines are designed to elevate your production to new heights, ensuring unmatched quality and performance.

Tailored Solutions:

We are committed to understanding your specific needs and providing solutions that cater to your unique requirements.

Product

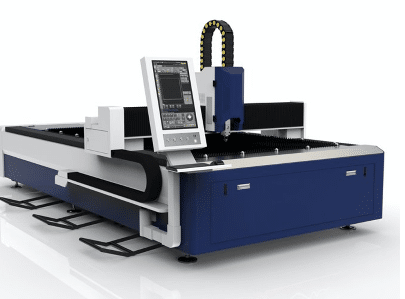

Open Type Single Table

Gantry double rack & pinion, double servo motor drive system, 1G acceleration to ensure higher production efficiency;

Tempering treatment and vibration aging to eliminate stress and achieve geometric accuracy of 0.03mm

Aluminium Crossbeam, light weight, high rigidity, high dynamic performance

Auto-focus laser cutting head, integrated with detailed cutting parameters, easy operation

Leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency and accuracy

Detection functions, automatic diagnosis, fault isolation, fault analysis and data display, fast trouble shooting, effectively reduces maintenance costs

Professional nesting software, automatic edge searching and sharp corner smoothing functions, high-speed piercing and fast array scanning cutting functions.

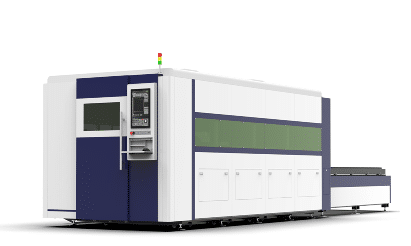

Closed Type Dual Exchange Table

Features:

Gantry double rack & pinion, double servo motor drive system, 1.2G acceleration to ensure higher production efficiency;

Plate welded heavy duty machine bed, heat treated, tempered and vibration aged to eliminate stress and achieve geometric stability and high accuracy

Aluminium Crossbeam, light weight, high rigidity, high dynamic performance

FSCUT 4000E the professional laser control system and laser cutting software have the functions of intelligent graphic layout, smooth processing of sharp corners, high speed piercing, etc., have super stability and anti-collision ability

Auto-focus laser cutting head, integrated with detailed cutting parameters, easy operation

Leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency and accuracy

Detection functions, automatic diagnosis, fault isolation, fault analysis and data display, fast trouble shooting, effectively reduces maintenance costs

Professional nesting software, automatic edge searching and sharp corner smoothing functions, high-speed piercing and fast array scanning cutting functions.

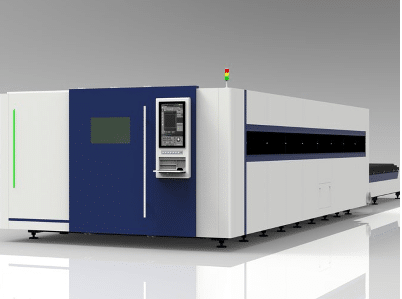

High Power Laser Cutting Machine

Features:

Gantry double rack & pinion, double servo motor drive system, 1.5G acceleration to ensure higher production efficiency;

Plate welded heavy duty machine bed, heat treated, tempered and vibration aged to eliminate stress and achieve geometric stability and high accuracy

Aluminium Crossbeam, light weight, high rigidity, high dynamic performance

FSCUT 8000E the professional laser control system and laser cutting software have the functions of intelligent graphic layout, smooth processing of sharp corners, high speed piercing, etc., have super stability and anti-collision ability

Auto-focus laser cutting head, integrated with detailed cutting parameters, easy operation

Leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency and accuracy

Detection functions, automatic diagnosis, fault isolation, fault analysis and data display, fast trouble shooting, effectively reduces maintenance costs

Professional nesting software, automatic edge searching and sharp corner smoothing functions, high-speed piercing and fast array scanning cutting functions.

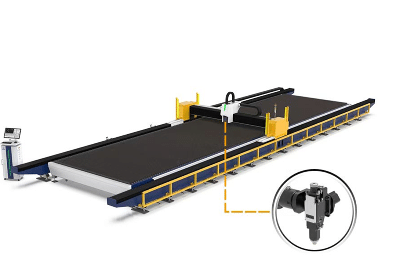

Large Format Gantry Style Laser

Features:

Ultra large format and high power with bevel cutting function

Modular design, plate welded heavy duty machine bed, heat treated, tempered and vibration aged to eliminate stress and achieve geometric stability and high accuracy

5 Axis, Bevel cutting, auto-focus laser cutting head

FSCUT 8000E the professional laser control system and laser cutting software have the functions of intelligent graphic layout, smooth processing of sharp corners, high speed piercing, piercing de-slag function, fusion cutting function

Professional nesting software, automatic edge searching and sharp corner smoothing functions, high-speed piercing and fast array scanning cutting functions.

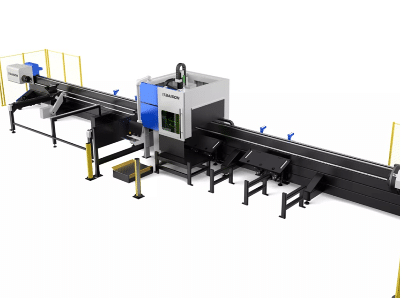

Tube laser cutting machine

Features:

2, 3 or 4 Chuck design depending on requirements

Square hole chuck design increases processing capacity

Various options of semi-automatic and automatic loading and unloading equipment

FSCUT5000S numerical control system based on Windows software, very easy to use

Capacitive laser cutting head, high induction accuracy, responsive, stable and reliable performance

High precision servo proportional valve, precise control of cutting auxiliary gas pressure and chuck clamping force

Automatic bundle feeding function (optional)

Complete cutting process parameter library, user-friendly parameter interface

The linear positioning speed up to100m/min, the rotary positioning speed up to 120 rpm

Professional tube cutting software to achieve “Full time cutting, Efficient cutting”

Automatic identification system of tube section (optional) for the mixed tubes feeding

LServo following support device, during tube feeding and rotating, support device keeps contacting with the surface of the tube

Laser welding machine

Features:

Integrated structure design, comply with majority of the laser source available in the market;

Low running cost, only 1~2Kw/h electricity and little nozzle cost;

Equipped with low gas pressure alarm function

Touch screen control panel, easy for parameter setting

Dual-temperature control water chiller, support both laser source and welding head, ensure long term stable operation;

O-type, Line-type and dot-type wobble welding types, swing width ranges 0~5mm;

Ergonomic design welding head for easy long-time operation.

https://rapidengineering.com.au/

Office Address

83 Victoria Street, SMITHFIELD, NSW, 2164

Email Address

info@rapidengineering.com.au

Telephone

( +61 ) 411 299 171